1989

With the regime change came a change in economic thinking and privatisation

From party-oriented, centrally led, and not entirely efficient management, there was a rapid transition to market-based practices supported by innovation, where, for example, new production standards, which were reflected in higher wages for employees, led to an increase in production of more than 30% at comparable costs. In 1991, almost “overnight”, I took up the position of economic deputy and left the company.

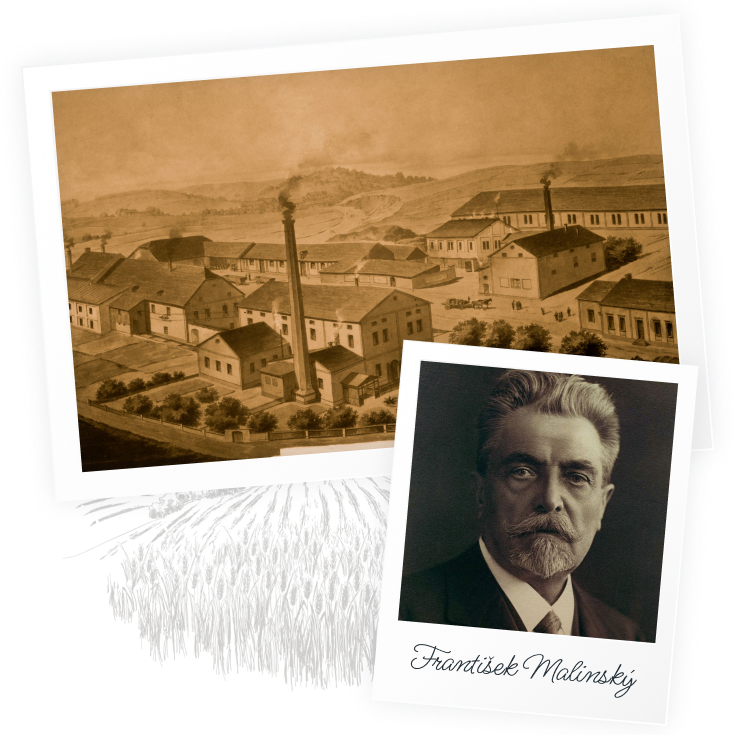

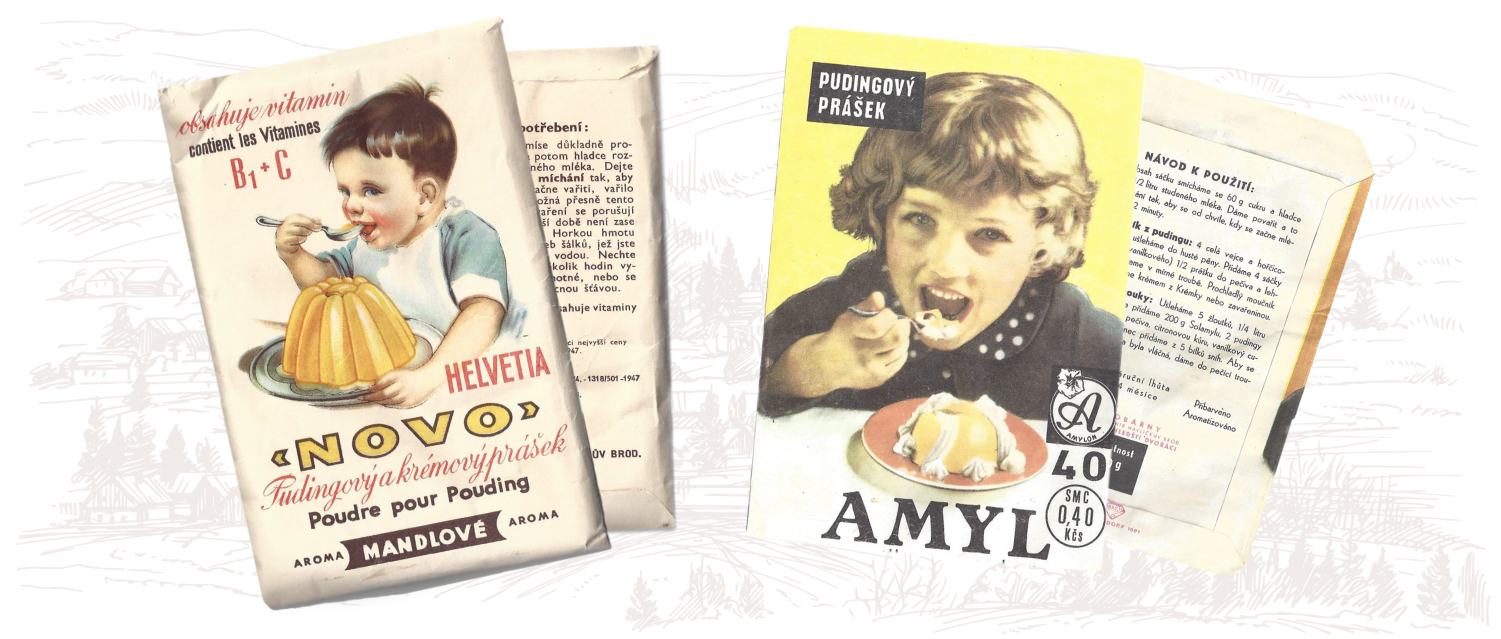

After the announcement of the coupon privatization, together with the plant director, we prepared a privatization project for the plant in Havlíčkův Brod, which was approved, but unfortunately without the most lucrative pudding production plant in Pohledštie Dvořáky near Havlíčkův Brod, which was sold to a Brazilian entrepreneur by the decision of the Ministry. In the privatisation project at that time, most of the shares were offered to the surrounding agricultural holdings, but unfortunately, due to lack of interest, the entire volume of shares was eventually subscribed by coupon privatisation. After about a year we decided to look for financial investors towards buying the shares from individual shareholders, which was successful and since then the company has been in Czech hands, now owned only by myself and two investors from outside the company.